Table of Content

The unique design of worm gears gives them the ability to stop quickly; this makes them the right choice for the operation of elevators. Though they can‘t make up the complete braking system, they work well with other braking system components as a safety measure. The precise mounting of a worm gear assembly is a critical part of its use. Several points of contact are required to avoid work loads over working the lead angle. The threaded wheels are made of an abrasive material that is harder than the metal to be ground.

Its operation relies on the sliding of the screw shaft and the nut threads with no ball bearings between them. The screw shaft and the nut are directly moving against each other on... Off road and construction vehicles require different amounts of torque to be delivered to each wheel. The need for a variation in torque is due to the terrain that the wheels of the vehicles have to traverse. Worm gears enable these types of vehicles to maneuver and drive over uneven ground without the fear of damage.

About Community

Reports of the calculation are displayed in the Summary of Messages area which is displayed after clicking the chevron in the right lower part of the Calculation tab. Click Results to display the HTML report with calculated values. Remember with worm farms you need to feed your worms regularly. It’s time to let the red wigglers or nightcrawlers (whichever compost worms you’ve decided on) into their new home aka your DIY worm bin.

A drilling machine, old newspapers, and of course, organic kitchen waste and food scraps. But it is much easier to harvest the compost since the equipment automatically separates worm castings from the worms. On the other hand, you can create a continuous flow worm farm like the commercial worm farms do.

Indoor Worm Bins or Outdoor Worm Bins?

I saw earlier it was only for solidworks and could not figure out the math to use the demo so I am happy to see fusion 360 support. Click More in the right lower corner of the Design tab to open the More Options area, where you can select other options for your calculation. We recommend that you select both cylindrical faces because gears are automatically put together. Use the tap on the bottom sump bin to drain off the worm tea every few weeks.

Talked to several people today and there are some reasonable priced gear cutters locally who can either cut it themselves or make a profile cutter for me realatively(?) cheaply. I've also been offered the loan of a proper indexing head to cut the teeth. It mounts on the cross slide and a fly cutter with a single point tool is used to cut the gashes.

Get Your Company Listed on this Power Page

They are normally used in conditions where cleanliness is a necessity such as food and beverage manufacturing. They are easy to clean and have smooth surfaces and exceptional durability. Much like bronze, brass is used to make the wheel gear; it is a softer metal and prevents wear on the shaft of the worm gear. The brass worm gear configuration is used for light loads since brass can only endure lower load amounts.

Keep checking on the worms regularly to see if they are doing their work of breaking down the foods in your new worm composter. The most popular type of worm used for composting is called the red wiggler that also goes by other names such as red worms, manure worms, and tiger worms. You might have to spend some time separating worms from the final compost when harvesting the castings.

If this is for a commercial product I suggest sourcing a readily available set that meets your needs. From experience, you will spend a lot of time and energy only to make something mediocre at best. And when it comes time for production you will probably need to outsource the gears. Doing it yourself will make you learn a lot but it may not be the best business solution. Janjigian explains that in a commercial oven there’s more room for the pizza, but in a backyard version, you have an intense heat source basically right next to the pie. That means there’s often more responsibility on you to rotate the pie once inside the oven to make sure it’s cooking evenly, around the circle, but also top and bottom.

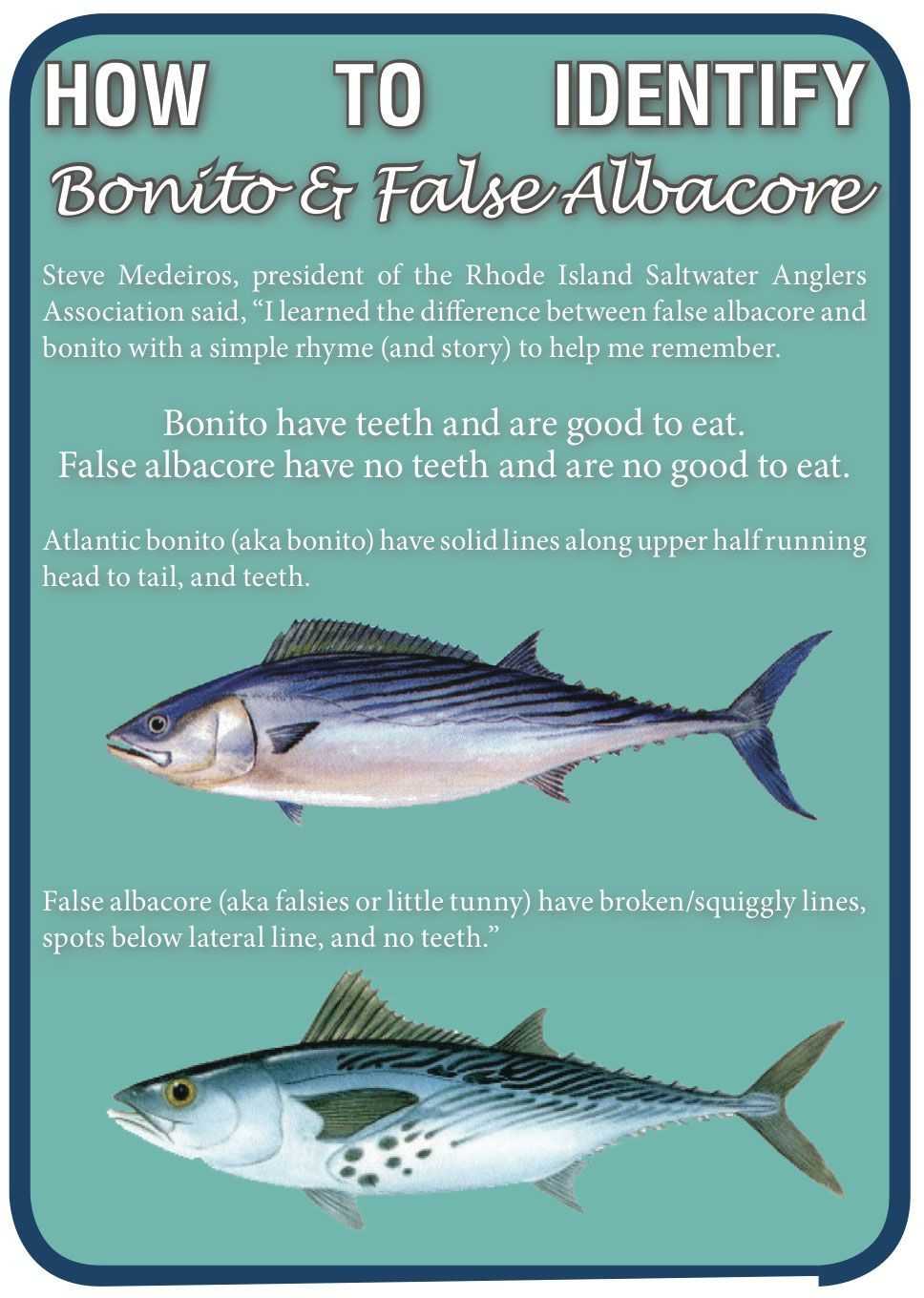

Non-throated worm gears are designed to handle small loads and are easy to make. The difference between single throat worm gears and double throat types is their shape. Double throat worm gears are concave on the gear and worm screw. The teeth of the gear and the shape of the worm threads are designed to increase the contact between the wheel and worm.

In worm gear assemblies, the axial pitch of the worm must be equal to the circular pitch of the larger gear, which is the first determination during assembly. Circular pitch is the distance between the teeth points on the pitch diameter, with axial pitch being the axial distance between the points of the teeth on the worm. The threads of the worm may be left handed or right handed.

A single throated worm gear has incurvate helical teeth designed around the worm for a contact line. This type of worm gear can withstand higher power without additional wear. In this type of worm gear, only one set of threads on the worm make contact with the worm wheel. Due to the fact that there is single contact, which produces significant friction, the worm has to be much harder and stronger than the wheel. A worm gear is a staggered shaft gear that creates motion between shafts using threads that are cut into a cylindrical bar to provide speed reduction. The combination of a worm wheel and worm are the components of a worm gear.

With proper mounting and installation, worm gear systems operate smoothly and quietly. The advantages of worm gears include noise and vibration reduction as well as compactness. They are made of hardened metals because of the amount of heat they generate. Rotate the bins after each harvesting so that the worms can migrate to another container and you can easily harvest worm castings from your worm composting efforts.

In the Worm gear section, select Component from the list. Use the Worm Gear Generator to insert a maximum of 2 gears at the same time. I used the provided coconut peat as bedding which needs to soak in water for 30 mins before using. This is the simplest way of building a worm farm all by yourself at a very low cost. Don’t overfeed them though, as this estimation is when they are in perfect conditions and as a beginner, things are likely not to be perfect.

No comments:

Post a Comment